Case Study: FLANjTAGS®

Joint assembly records are essential in keeping flange break processes efficient, safe, and accurate. Flange tags provide a complete status of all steps of the flange break process, indicating the risk level and history of each joint in order for personnel to carry out a leak-free and safe start-up.

THE PROBLEM

Problem 1

Bolted flange joints with unreliable and non-durable Joint Assembly Records (Flange Tags) can result in safety, environmental, and quality control challenges.

Due to the nature of their purpose, flange tagging systems are often in service for extended periods of time. During this time, they are exposed to harsh conditions such as wind, UV, and frost.

Non-compliant tags made from flimsy materials are likely to fade, become brittle or even break away from the joint in these conditions. This means users can no longer see the critical details needed to carry out safety inspections or maintenance to the joint. It can result in costly and dangerous leaks during the start-up process.

Additionally, short-life tags made from weak materials are more likely to need regular replacements. This is not only costly for organisations but also increases the amount of waste produced causing a detrimental impact on the environment.

Problem 2

Joint Assembly Records without customisations such as colour coding and tailored information fields, can result in safety and quality control challenges.

Every organisation carries out flange management processes slightly differently, and every flange joint will come with its own individual risks and requirements. Therefore, when it comes to selecting the correct joint assembly record, there is no one size fits all solution.

Many flange tags come in standard template designs based on industry-standard guidelines, these standard tags have limitations in terms of the amount of detail and information included in them. For companies dealing with the maintenance of bolted flange joints, especially in large quantities, these standard tags are not suitable as they can be easily confused with other tags. This can lead to dangerous and potentially costly confusion.

THE SOLUTION

Always follow the ASME PCC-1 Guidelines

ASME PCC-1-2022 is a document written by specialists across the bolting industry, and it addresses the key factors involved in bolting principles and the assembly of bolted flange joints. ASME PCC-1 is considered the standard for bolting joint connectors within many major petrochemical companies worldwide.

Section 13 of the PCC-1 document covers guidelines for recording bolted flange joint assembly and outlines the recommended requirements for a compliant flange tagging system.

ASME PCC-1-2022 recommends the use of FLANjTAGS®

Our FLANjTAGS® are noted in the ASME PCC-1 document as being compliant for joints of ALL risk levels. These multi-part tear-off flange tags are made with Prism polypropylene, a unique material designed to withstand harsh environments anywhere around the world. It’s made from a durable material which is weather resistant and fade resistant, ensuring important safety messages remain clear for longer, no matter what the conditions.

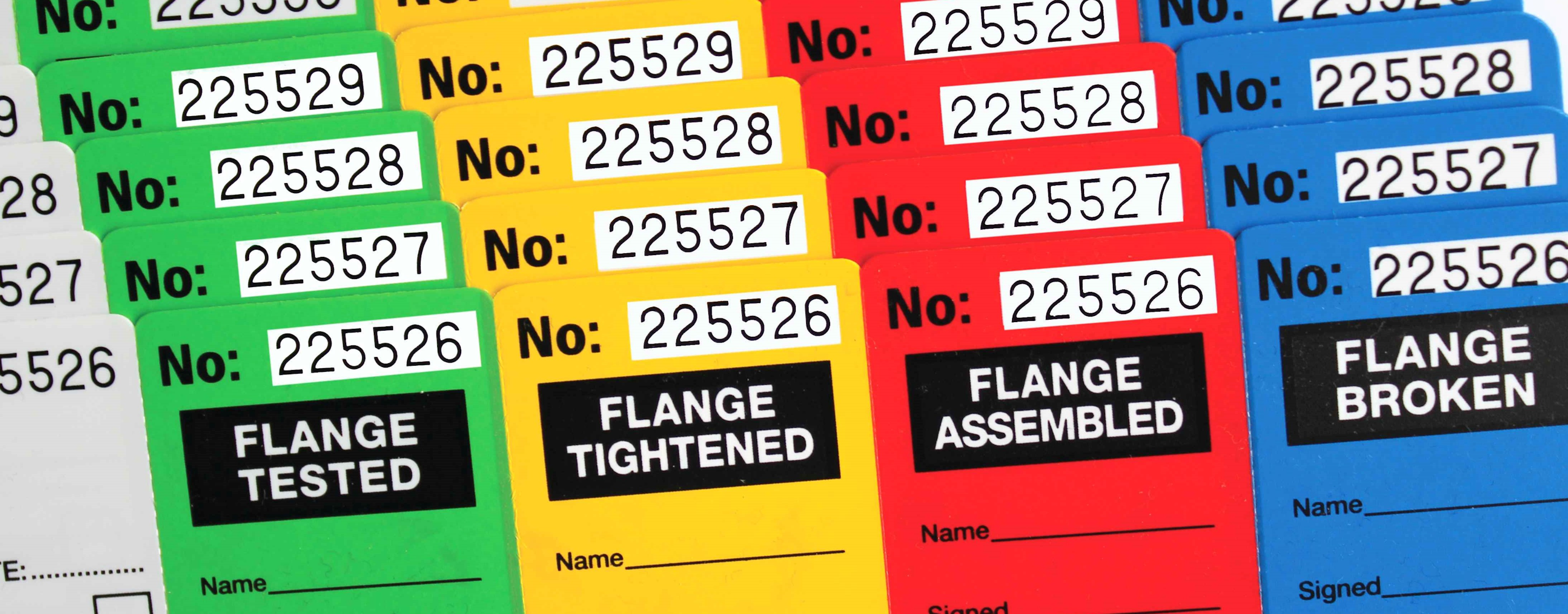

When dealing with such high-risk processes, mix-ups and mistakes simply can’t be made. FLANjTAGS® provide a highly visual status record to show that all steps of the flange break process have been safely carried out. Our FLANjTAGS® are customisable, allowing you to colour code and personalise the design to fit seamlessly around your existing processes. This eliminates the risk of any duplication across different sites and ensures all safety information is clear and easy to understand - essential for a leak-free start-up.

FLANjTAGS® Specification

- Multiple tear-off sections

- 100% recyclable

- Material: Prism polypropylene

- UV resistant

- Freeze resistant

- Fully customisable design

- Available with QR codes / barcodes

- Available with VARiTAG® unique numbering

- All corners rounded to reduce cut risk

- Bilingual or dual languages available

- ISO 4892-2:2013 Tested Material

- ASME PCC-1-2022 Recommended Tag

The FLANjTAGS® flange management tagging system is a turnkey solution for the petrochemical industry, on their journey towards ZERO. ZERO Incidents, ZERO emissions.

results

See what BP had to say about our safety solutions:

"REGALTAGS have been a supplier to BP for many years. They have tailored our needs within their business requirements without any hitches.

They are always there to guide us and suggest ever better improvements to assist us. The samples they produce, and the delivery is excellent. I have no hesitation in recommending working with them."

Subscribe

Join 10,000+ others receiving our monthly updates. Free Tag knowledge delivered straight to your inbox.