3 Ways to Create a Safe Work Culture in High-Risk Jobs

When working in high-risk environments, creating a safe work culture can make all the difference in keeping personnel accident-free and out of harm's way.

Adherence to health, safety and environmental regulations have long been a consideration for corporations across the globe, especially those within the extraction and production sectors.

Critical industries such as the oil and gas, energy, and manufacturing industry, face some of the harshest working environments in the world. To mitigate the risk of workplace incidents that could potentially cause serious harm and lost time, these industries must enforce and maintain a safe work culture.

This article will explore three key ways workplaces within high-risk industries create a safer work culture.

1: Ensure all employees are given appropriate safety training

Before implementing any safety procedures, employees must know the potential hazards and risks in their workplace and the steps they need to take to ensure that themselves and their colleagues remain safe. Safety training should happen as part of onboarding and should also be an ongoing commitment through refresher training.

2: Implement Efficient Safety Tagging Systems

Working in critical industries often means working in hazardous and potentially dangerous environments where accidents can occur. From machinery to pipes and electrical equipment, there are many possible dangers in the workplace that need to be regularly inspected, managed, and maintained in order to keep processes running smoothly and safely.

Safety tagging control systems, also known as safety tags, are among the various methods that businesses in critical industries use to manage hazards and reduce risks in the workplace. These systems provide a straightforward yet efficient approach to identifying and labelling hazards and keeping track of inspections and maintenance activities.

These tags should be clear and durable, among other compulsory requirements which we explored in our previous blog titled “How to ensure your workplace safety tags are compliant”.

Some critical safety tagging systems include:

Inspection tags: While machinery needs routine maintenance to ensure safety, regular inspections are important too. Inspections reduce the chance of equipment failure in the workplace and aim to spot any potential problems before they cause a threat.

Made to identify the piece of equipment, location of inspection, dates, and personnel responsible for each check-up, Inspection Tags allow you to record everything needed.

These tags are often used for the inspection of ladders and lifting equipment, or for ATEX Inspections.

Isolation tags: Isolation Tags are used to clearly identify equipment or systems that are in an isolated state, in order to prevent accidental energization during maintenance or repair work.

Isolation tags place the responsibility onto a named individual and encourage awareness and compliance with safety procedures. This eliminates downtime by facilitating effective communication among workforces.

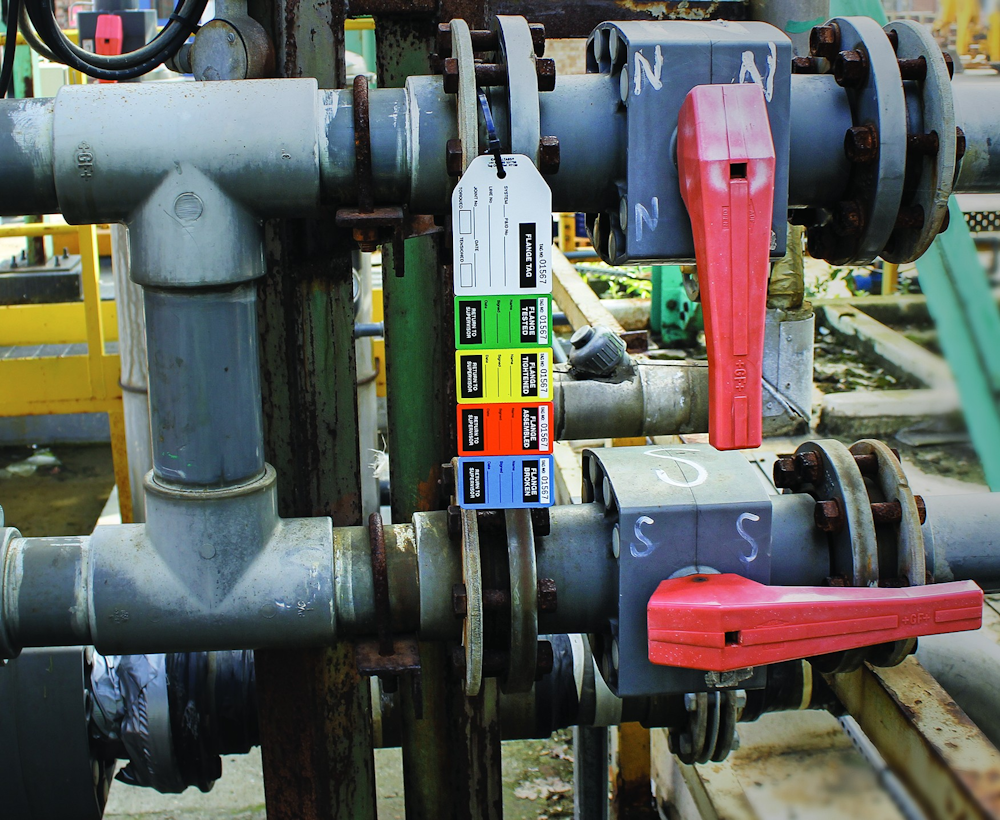

Process management tags: Effective communication is essential for ensuring the safety of staff and the security of machinery. Team members need to be aware of the progress of each stage of the process and know which steps have already been completed safely. This is where multi-part Process Management Tags play a crucial role.

By using multi-part tags like Flange Tags and Hire Tags, a clear and highly visible record of the inspection or management process can be communicated. These tags provide an efficient way to convey the current status of the process visually.

Lockout tags: Machinery plays a significant role in the day-to-day operations of many organizations, and regular maintenance is crucial to keep them running smoothly. Whether it is a pump in an oil rig or a conveyor belt in a production line, eventually, equipment needs to be shut down for servicing.

Lockout Tags are used in such situations to inform others that the machinery is not in use and is being serviced. Lockout Tags clearly inform everyone that the machinery is not to be turned on, which is important to avoid potential harm to the maintenance team or anyone else who may operate the equipment.

Identification tags: When it comes to creating a safe work environment, having critical information readily available to your team is so important.

Identification Tags are often relied on to carry information vital to the workforce's safety.

3: Invest in Durable and Highly Visual Workplace Safety Signs

Another vital component in creating a safe work environment is to invest in compliant safety signage. Safety signs serve to alert workers to potential hazards and provide important instructions for avoiding accidents and injuries.

According to HSE, safety signs and signals are required where a significant risk to the health and safety of employees and others remains. These signs should be clear and durable, among other compulsory requirements which we explored in our previous blog titled “5 essential requirements for workplace safety signs”.

There are four main types of safety signs that are commonly used in the workplace, and these include:

Prohibition signs: Prohibition signs are typically used to warn workers not to engage in certain activities that could be dangerous or pose a risk to their safety.

Warning signs: Warning signs are typically used to caution workers about conditions that could cause injury or harm, and to provide important instructions for avoiding accidents.

Mandatory signs: Mandatory signs are typically used to inform workers of the safety measures that must be followed in a particular area of the workplace.

Emergency signs: Emergency signs are typically used to help workers quickly and easily find the equipment or procedures they need in the event of an emergency.

Create and Maintain a Safe Work Culture with REGALTAGS

At REGALTAGS, we provide tough workplace safety tagging and signage that meets all safety specifications and needs.

We believe every safety process is unique. That’s why all our solutions are completely customisable so you can ensure they’ll be most effective for you. Our designers can guide you through with up-to-date knowledge of industry best practices and 1000’s of tried and tested existing signs for inspiration.

The durability of your signs and tags is also important so that they always remain intact to carry out their important role. We provide a range of durable safety solutions fit for any conditions.

In our range of safety signs, and tags we offer:

- UV and fade resistance

- Freeze-proof

- Lightweight options

- 100% recyclable materials

- Scratch- and scuff-resistance

- Customisability

If you’d like to find out more about how we can help with your safety processes, contact our friendly team at REGALTAGS® today. We’re more than happy to answer any questions you have and can guide you through each material option.

Subscribe

Join 10,000+ others receiving our monthly updates. Free Tag knowledge delivered straight to your inbox.